ABOUT INNOVEX BOWL FEEDERS

Welcome to INNOVEX Bowl Feeders : Your partner in feeding and positioning parts. We are bowl feeders manufacturers with over 20 years of industry experience. INNOVEX Bowl Feeders has established itself as a leader in manufacturing innovative vibratory feeding equipment.

Strategically located in Bengaluru. We serve clients all over India, offering for the Fasteners ,pharmaceutical, Automotive, Electrical , Automation, FMCG & manufacturing industry

At INNOVEX Bowl Feeders, we are committed to excellence in the production of feeding and positioning systems. Our products not only ensure precise and efficient feeding of your components but also optimize your production processes, increasing productivity and reducing operational costs.

Feeding systems that transform your production.

Vibratory Feeder Manufacturers: Leading Innovators in Feeding Solutions

INNOVEX, we take pride in being one of the top vibratory feeder manufacturers in the industry. With good experience, we have established ourselves as trusted bowl feeder manufacturers, known for delivering reliable and efficient automated solutions tailored to the unique needs of our clients. Our team of experts specializes in the design and production of high-quality vibratory bowl feeders, ensuring optimal performance across a variety of industries.

As a dedicated vibrating feeder company, we are committed to advancing feeding technology. Our innovative approach to automation allows us to stay at the forefront of the market, providing robust and efficient feeding systems that streamline production processes. From custom designs to standard models, our offerings cater to businesses seeking premium solutions from top-tier feeder bowl manufacturers.

Whether you need a specific solution or a full-scale automated feeding system, INNOVEX is your go-to partner. Our reputation as leading vibrating feeder manufacturers is built on our commitment to precision, quality, and customer satisfaction. to discover how our feeding systems can help improve efficiency and productivity in your operations.

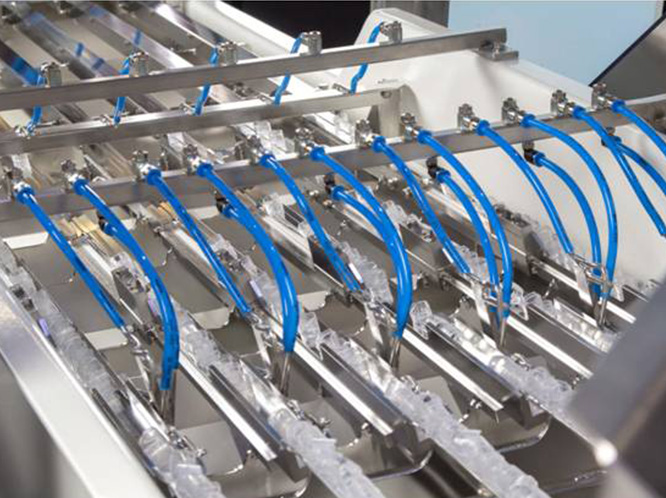

Bowl Feeder – Multiple Parallel Tracks

Linear Feeder – Multiple Tracks

Bowl Feeder Sound Proof and Dust Proof Enclosure

Why choose us

COMMITMENT TO QUALITY AND INNOVATIONWhat sets us apart is our unparalleled customer attention and our commitment to quality and innovation. Every equipment we manufacture is the result of our experience and technical expertise, backed by a team of passionate and dedicated professionals.

Whether you run a small local business or a global corporation, at INNOVEX Bowl Feeders, you’ll find the perfect solution for your feeding and positioning needs.

Trust INNOVEX Bowl Feeders to drive your success in the manufacturing industry, wherever you are in the world. Explore our feeding systems and discover how we can take your production to the next level.

Projects completed for our respected clients.

Experienced professionals serving to clients.

Years experience in business & consulting.

Our working process - how we work for our customers

- 1. Understanding Client Needs

- 2. Tailored Solutions Based on Expert Consultation

- 3. Design Phase: Tailoring from the Ground Up

- 4. Cutting-Edge Manufacturing Techniques

- 5. Rigorous Testing and Quality Control

- 6. Continuous Support and Adaptability

The manufacturing process starts with a thorough understanding of the client’s production requirements. Our skilled technical-commercial specialists have in-depth conversations with customers to gather information about the type of process they run and their specific feeding system needs.

Once the client provides details about their production line, our highly experienced technical sales team prepares a custom proposal. This proposal identifies the system that best suits the client’s project, taking into consideration all the variables involved in their process. The goal is to offer a feeding solution that is not only functional but optimized for efficiency and reliability.

Once the proposal is approved, we seamlessly transition into the design phase. customization is woven into the fabric of our manufacturing process from the outset. Every detail of the bowl feeder—ranging from the bowl design to the feeding mechanisms and material selections—is meticulously crafted to meet the client’s unique specifications.

Our engineers conduct a thorough analysis of the client’s requirements, taking into account factors such as the types of parts to be fed, desired production speed, and orientation needs.

This meticulous attention to detail guarantees a smooth and dependable feeding process.

To ensure durability and long-lasting performance, we carefully select premium materials, such as stainless steel, for our feeders’ construction. These materials are chosen for their exceptional strength, resistance to wear, and ability to withstand the vibrations essential for efficient operation.

Once the design is finalized, our skilled technicians use state-of-the-art manufacturing techniques, and precision welding, to bring the design to life. This ensures that every component is crafted with accuracy, allowing for smooth operation and minimal maintenance.

After assembly, each bowl feeder undergoes extensive testing to ensure it meets our strict quality standards. We simulate real production conditions, checking for part orientation accuracy, feed rates, and vibration consistency. This ensures that every feeder we deliver is reliable, efficient, and ready for immediate integration into the client’s production line.

our relationship with the client doesn’t end with delivery. We offer ongoing support to ensure that the bowl feeder continues to meet the needs of the production line as it evolves. If necessary, we can make adjustments ensuring that our clients always benefit from the most efficient and cost-effective feeding solutions.

Explore our bowl feeder manufacturing process at INNOVEX in this insightful video. Witness the meticulous techniques and skilled craftsmanship that go into creating our feeders, showcasing our unwavering dedication to excellence.